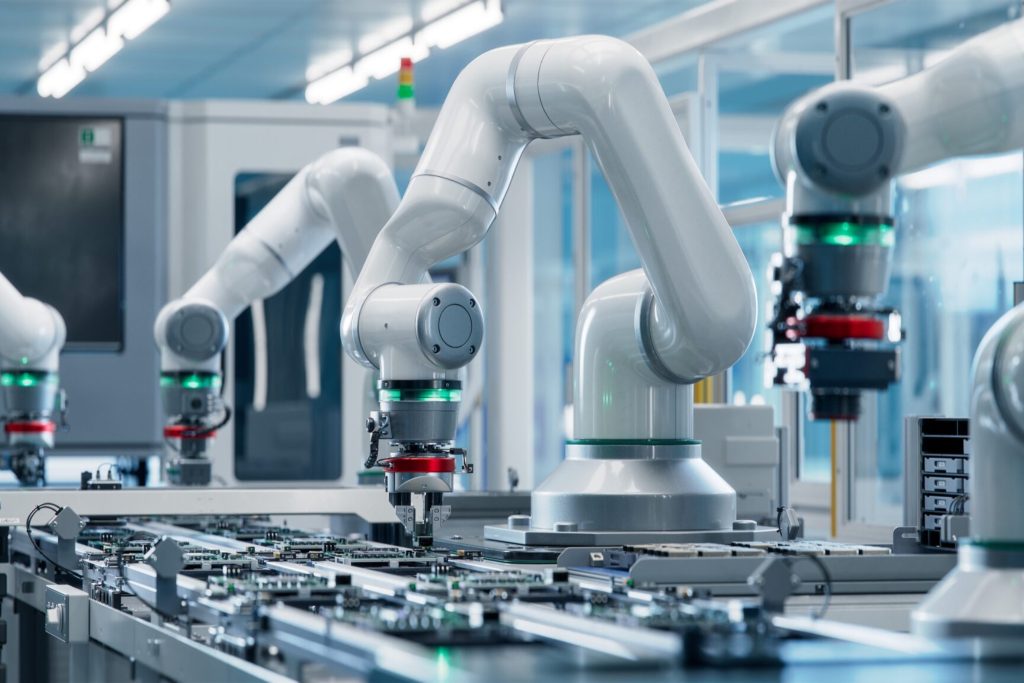

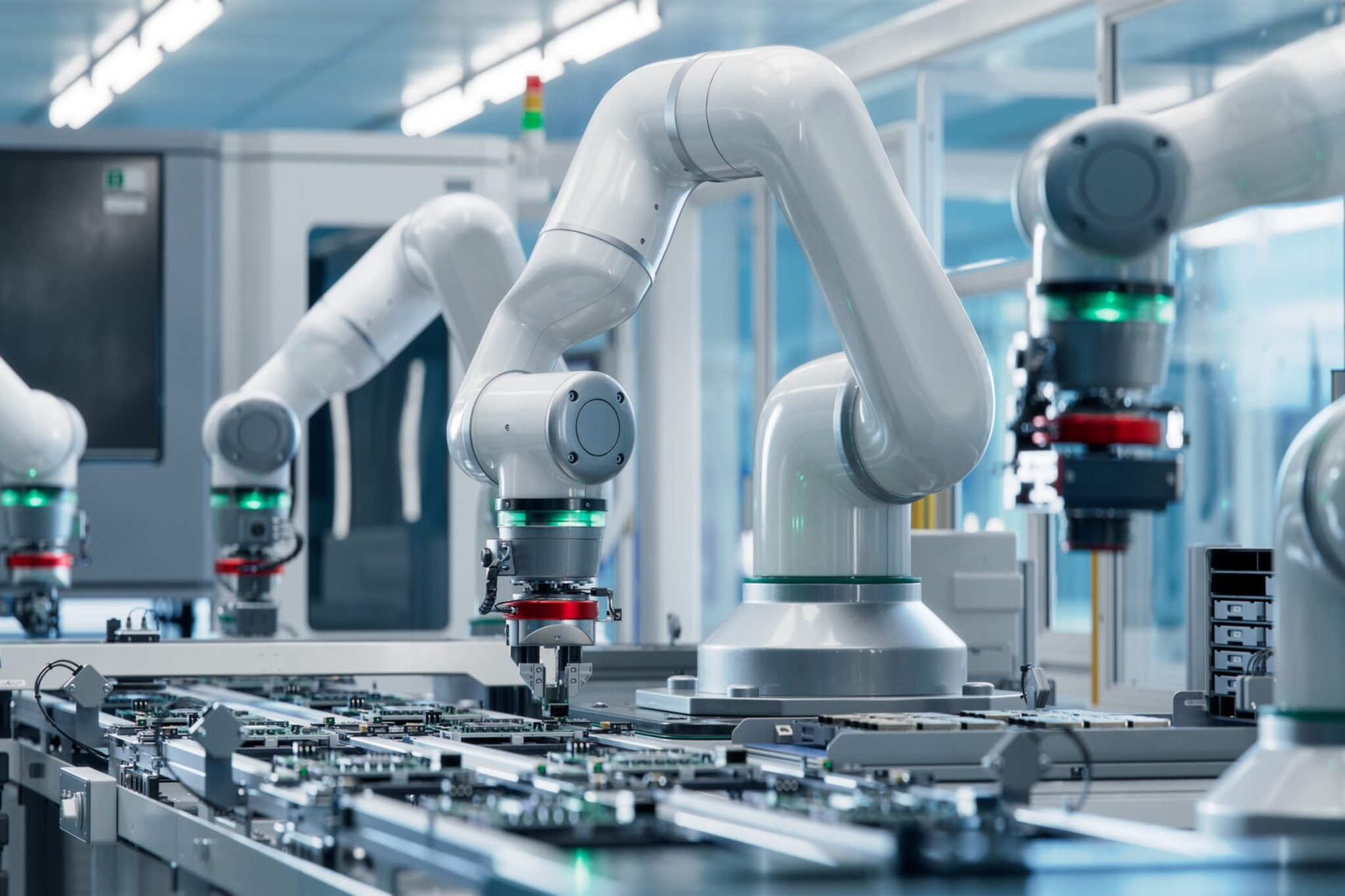

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for manufacturing high-tech components like semiconductors, microchips, and circuit boards. Ultrapure water (UPW) is essential for cleaning, rinsing, and etching processes, where even trace contaminants can lead to defects or performance issues.

Achieving and maintaining such high water quality involves removing particles, ions, organics, and dissolved gases to extremely low levels. Specialized treatment systems like reverse osmosis, deionization, and ultrafiltration are used, alongside real-time monitoring for continuous control. Proper water treatment ensures both the reliability of electronic products and environmental compliance through efficient wastewater management and recycling.

Pure process water for microelectronics production

- Challenges:

- Achieve UPW required for semiconductor and electronic component production.

- Removing all ions, particles, organics, dissolved gases, and other impurities to extremely low levels.

- Maintaining a resistivity of 18.2 MΩ-cm at 25°C (indicating minimal dissolved ions).

- Particle contamination, trace metals, ions, and minerals, must be reduced to less than 1 particle per liter to avoid failures in electronics.

- Eliminate organic contaminants (DOC <1ppb) that can lead to corrosion and degradation of electronic components.

- Reduce silica (<1 ppb) to avoid defects during manufacturing.

- Requirements for zero-tolerance on bacteria, biofilms, and endotoxins that could cause manufacturing defects and reliability issues.

- Any fluctuations in water quality can lead to production defects or downtime. Minor deviations in pH or temperature can lead to issues with thin film deposition or surface defects. Dissolved gases can cause corrosion and affect precision in manufacturing processes.

- Treatment Solutions:

- Reverse osmosis (RO), continuous electro deionization (CEDI), UV oxidation, and organic scavengers to achieve high purity.

- Microfiltration, ultrafiltration, nanofiltration, and point-of-use filtration.

- Ion-exchange resins, advanced polishing techniques.

- Advanced oxidation processes (AOPs), and degasification.

- Chemical disinfection, ozone treatment, and sub-micron filtration (< 0.22 micron) systems.

- Continuous water quality monitoring systems with automated sensors and real-time analyzers for resistivity, TOC, particle count, pH, silica, and bacterial monitoring with integrated control systems.

- Degasification technologies such as vacuum degassing, membrane contactors, and chemical degasification methods.

Discover KontrolKem’s comprehensive wastewater treatment solutions, including advanced chemical treatments and equipment

>> Find out more

Wastewater treatment in the electronics industry is critical due to the complex and hazardous waste streams generated during semiconductor and electronic component manufacturing. This wastewater contains a mix of heavy metals, acids, bases, organic solvents, and other contaminants that pose significant environmental and operational challenges. Advanced treatment processes are required to meet stringent regulatory standards, protect equipment, and minimize environmental impact.

The industry also focuses on water recycling and reuse, reducing both freshwater consumption and the volume of wastewater discharged. By employing specialized technologies, the electronics industry ensures safe and sustainable wastewater management throughout its production processes.

Challenges:

- Eliminate toxic heavy metals like copper, lead, nickel, and chromium that are prevalent in wastewater from metal deposition, etching, and soldering. Strict regulatory limits require removal down to parts per billion (ppb) levels.

- Neutralize highly acidic or alkaline chemicals used during cleaning, etching, and plating processes, resulting in wastewater that can be corrosive and harmful if untreated.

- Reduce fluoride levels from wastewater generated by etching and cleaning processes in semiconductor manufacturing.

- Remove organic compounds, such as solvents and photoresists which are toxic and contribute to biofilm formation.

- Reactive and colloidal silica, is commonly found in wastewater due to its use in semiconductor cleaning processes, and it can lead to scale formation in pipes and membranes.

- Bacteria and biofilms can form in wastewater systems, leading to clogging, contamination of ultrapure water systems, and reduced process efficiency.

- Recycle treated wastewater for reuse in manufacturing processes, reducing water consumption and minimizing environmental impact.

Treatment Solutions:

- Coagulation and flocculation: Use coagulants to bind colloidal ions and flocculants to agglomerate for removal.

- Chemical Precipitation: Convert dissolved metals into solid metal hydroxides through pH adjustment.

- Chemical Neutralization: Use acids or bases (e.g., sulfuric acid or lime) to adjust the pH of wastewater to neutral (pH 6-9).

- Automated pH Control Systems: Monitor and adjust pH in real time to ensure compliance with discharge standards.

- Ion Exchange: Use resins to remove metal ions from wastewater..

- Advanced Oxidation Processes (AOPs): Use ozone, hydrogen peroxide, or UV light to break down organic compounds.

- Sedimentation and Clarification: Settle out solids by gravity in clarifiers.

- Filtration (Micro/Ultra): Use microfiltration or ultrafiltration membranes to physically remove particles from the wastewater.

- Dissolved Air Flotation (DAF): Float out suspended solids through the introduction of fine air bubbles.

- Zero Liquid Discharge (ZLD): Minimize wastewater discharge by concentrating waste streams and recovering nearly all water.

Optimize your industrial process with our expert water treatment solutions, designed to improve efficiency and protect the environment. Contact us today to schedule a meeting and discover how we can help you achieve your goals!

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for…

Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants…

Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the…

Paper

Water treatment plays a vital role in the paper industry, where large volumes of water…

Automotive

In the automotive industry, paint application is a crucial process that significantly influences the final…

Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety…

Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring…

Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with…

Metalcasting

Effective water treatment is essential in the metal casting industry to ensure optimal cooling and…