Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants generated during metal finishing operations. With heavy metals, toxic chemicals, and complexing agents prevalent in wastewater, effective treatment is essential for regulatory compliance and environmental protection. Key focal points include heavy metal removal, pH control, cyanide destruction, and management of suspended solids.

Additionally, the industry emphasizes the reduction of total dissolved solids (TDS) and the importance of water reuse and recycling to enhance sustainability and reduce operational costs. By employing advanced treatment technologies and continuous monitoring, electroplating facilities can ensure their wastewater meets stringent discharge standards while minimizing environmental impact.

Discover KontrolKem’s comprehensive wastewater treatment solutions, including advanced chemical treatments and equipment

>> Find out more

Removal of toxic elements in electroplating wastewater

Challenges:

- Heavy metals removal like chromium, nickel, zinc, copper, cadmium, and others. Wastewater from these operations often contains high levels of toxic metals, which must be removed to meet environmental discharge standards.

- Electroplating wastewater often has extreme pH values, either highly acidic or basic, depending on the specific metal plating process. Effluent must be neutralized to meet discharge standards.

- Cyanide is used in many electroplating baths, especially for gold, silver, and zinc plating. It is highly toxic and must be fully destroyed before wastewater is discharged.

- Chromium plating uses highly toxic hexavalent chromium (Cr⁶⁺), which must be reduced to the less toxic trivalent chromium (Cr³⁺) before it can be treated or removed.

- Electroplating processes often involve oil-based substances used in degreasing or as part of the plating baths. Oil and grease in wastewater can interfere with treatment processes and need to be removed.

- Many electroplating baths use complexing agents like EDTA or ammonia to keep metals in solution. These chelating agents make metal removal more difficult as they bind tightly to metals and prevent their precipitation.

- Water conservation and reuse are increasingly important in electroplating due to both environmental concerns and cost savings.

- Due to the variability of electroplating processes and the toxicity of the wastewater, continuous monitoring and automated control systems are often implemented to ensure optimal treatment.

Treatment solutions:

- Chemical Precipitation: Metal ions are converted into insoluble metal hydroxides or sulfides by adjusting the pH of the water, allowing them to be filtered out.

- Chemical Reduction: Chemical agents reduce hexavalent chromium to trivalent chromium, which can then be precipitated as chromium hydroxide.

- Coagulation and Flocculation: These methods use chemical agents to gather oil particles into larger clumps for easier removal.

- Selective Ion Exchange: Specialized resins used to capture chelated metals are often used with closed-loop systems to recirculate treated water back into the plating process to reduce the need for freshwater.

- Membrane filtration: is used in electroplating wastewater treatment to separate dissolved metals, solids, and contaminants. These membranes offer high separation efficiency and can be used as a final polishing step.

- Alkaline Chlorination: Cyanide is oxidized by chlorine or hypochlorite in a high-pH environment to form cyanate, which is further broken down into harmless nitrogen and carbon dioxide.

- Ozone Treatment: Ozone can be used as an oxidizer to break down cyanide into less harmful compounds.

- Dissolved Air Flotation (DAF): This technique floats oil and grease to the surface for removal.

- Sludge Dewatering: Technologies such as filter presses or centrifuges are used to reduce the volume of sludge, making it easier and less costly to dispose of.

Real-time monitoring: pH, metal concentration, and flow rate monitoring together with automated dosing of treatment chemicals to maintain ideal treatment conditions.

Optimize your industrial process with our expert water treatment solutions, designed to improve efficiency and protect the environment. Contact us today to schedule a meeting and discover how we can help you achieve your goals!

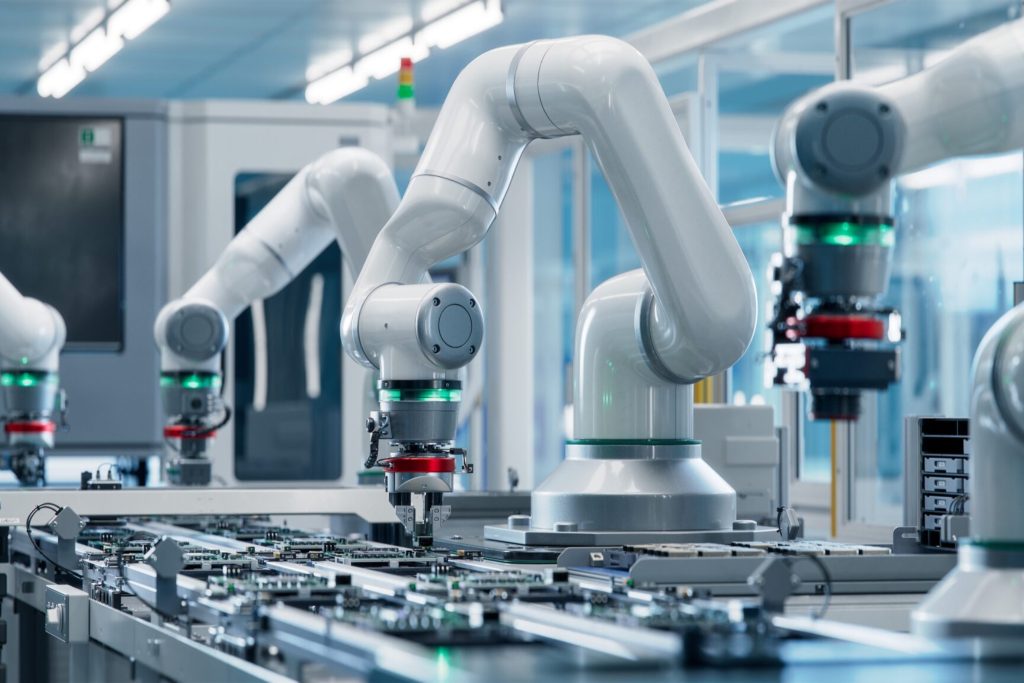

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for…

Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants…

Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the…

Paper

Water treatment plays a vital role in the paper industry, where large volumes of water…

Automotive

In the automotive industry, paint application is a crucial process that significantly influences the final…

Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety…

Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring…

Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with…

Metalcasting

Effective water treatment is essential in the metal casting industry to ensure optimal cooling and…