Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the Earth’s internal heat to generate power and provide heating solutions. As geothermal resources become increasingly important, effective water treatment strategies are essential to ensure the sustainability and efficiency of these operations. This involves addressing the unique challenges posed by geothermal fluids, which often contain high levels of minerals and corrosive compounds.

Water treatment in the geothermal sector not only helps maintain equipment longevity but also mitigates environmental impacts. By focusing on scaling control, corrosion mitigation, and the removal of harmful gases, the industry can enhance operational efficiency while adhering to regulatory standards. These chemical treatments not only enhance the lifespan of the equipment but also optimize heat transfer processes, ultimately leading to increased energy production.

Discover how KontrolKem’s innovative cooling water treatment solutions can enhance the efficiency and longevity of your industrial cooling systems.

>> Find out more

Geothermal water scaling and corrosion

Challenges:

- Mineral Precipitation: High-temperature geothermal fluids often contain dissolved minerals that can precipitate and form scale. Magnesium hydroxide, strontium sulfate, and barium sulfate are also common contributors to scaling.

- Silica: Commonly found in geothermal fluids, silica can precipitate as it cools, forming hard deposits that reduce heat transfer efficiency.

- High temperatures in geothermal systems can enhance the corrosive effects of dissolved gases and ions. Elevated pressure can also increase the solubility of corrosive compounds.

- Hydrogen Sulfide: A common gas in geothermal fluids that is highly corrosive, especially to metals like carbon steel. It can form sulfuric acid when oxidized, leading to severe corrosion.

- Carbon Dioxide: When dissolved in water, CO₂ can lower the pH, increasing acidity and promoting corrosion.

- Chlorides concentrations can lead to pitting corrosion, which creates localized damage on metal surfaces.

- Cooling down: As geothermal fluids pass through heat exchangers and cool down, the solubility of certain minerals decreases, leading to precipitation and scale formation.

- Alkalinity: Changes in pH can cause the precipitation of calcium and magnesium salts, contributing to scaling problems.

- Variable Water Chemistry: Geothermal fluids can vary significantly in composition and concentration of dissolved salts, necessitating tailored treatment approaches for different sites.

- Temperature Extremes: High temperatures can limit the effectiveness of some chemical treatments, requiring specialized inhibitors that can withstand these conditions.

Treatment Solutions:

- Scaling Inhibitors: Specialized scaling inhibitors are used to prevent the precipitation of minerals. These chemicals work by interfering with the crystallization process, reducing the likelihood of scale formation on heat exchangers and piping. Inhibit scale formation by interfering with the crystal growth of calcium carbonate and silica These act as dispersants that prevent particles from aggregating and forming scale. Some are specifically designed to stabilize dissolved silica, reducing the likelihood of precipitation.

- Corrosion Inhibitors: Various inhibitors, such as amines, film-forming agents, and organic acids, are employed to create protective films on metal surfaces, thereby reducing the corrosion rate. These chemicals can effectively counteract the corrosive effects of acids and dissolved gases like hydrogen sulfide. Amines: They form protective films on metal surfaces, reducing corrosion rates in the presence of acidic gases like H₂S. Film-Forming Agents: Organic compounds that create a protective barrier on metal surfaces, inhibiting corrosion from chloride ions and acidic conditions. Organic Acids: Some acids, when present in low concentrations, can help passivate metal surfaces, reducing their reactivity.

- Continuous monitoring: the corrosiveness of geothermal fluids and adjust chemical treatments accordingly.

- Precise Chemical Pumps: These pumps deliver precise amounts of inhibitors based on real-time monitoring of water chemistry.

- Corrosion and Scale Coupons: Placed in the system to monitor material degradation and scaling over time, providing insights into corrosion rates and deposit formation.

- LPR Probes: Installed in various parts of the system to measure corrosion rates in real-time.

- Test heat exchangers: replicating conditions in real heat exchangers monitoring scaling and corrosion

Optimize your industrial process with our expert water treatment solutions, designed to improve efficiency and protect the environment. Contact us today to schedule a meeting and discover how we can help you achieve your goals!

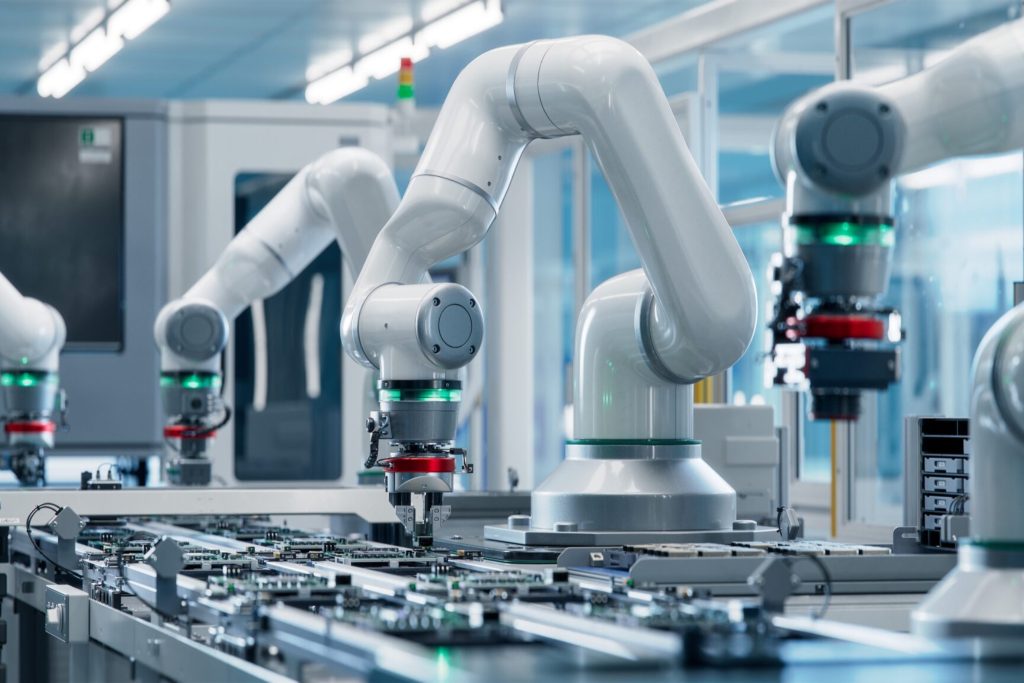

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for…

Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants…

Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the…

Paper

Water treatment plays a vital role in the paper industry, where large volumes of water…

Automotive

In the automotive industry, paint application is a crucial process that significantly influences the final…

Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety…

Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring…

Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with…

Metalcasting

Effective water treatment is essential in the metal casting industry to ensure optimal cooling and…