Paper

Water treatment plays a vital role in the paper industry, where large volumes of water are required for key production processes such as pulping, bleaching, and paper formation. Managing water quality and wastewater effectively is critical to maintaining operational efficiency, ensuring regulatory compliance, and reducing the environmental footprint of paper mills. To address these challenges, the industry employs a range of specialized water treatment strategies tailored to the unique demands of its operations. These strategies focus on source water quality management, reducing chemical oxygen demand (COD), recycling process water, treating bleaching effluents, and handling heavy metals and sludge.

By leveraging advanced technologies and sustainable practices, the paper industry can optimize water usage, minimize waste, and enhance overall environmental performance. The implementation of closed-loop systems, real-time monitoring, and energy-efficient processes helps mills reduce their dependency on fresh water, meet discharge regulations, and reduce treatment costs.

Learn how KontrolKem’s comprehensive boiler water treatment solutions, including advanced chemicals and equipment, prevent scale formation, corrosion, and other issues.

>> Find out more

Discover KontrolKem’s comprehensive wastewater treatment solutions, including advanced chemical treatments and equipment

>> Find out more

Paper mill wastewater

Challenges

- High COD Levels: The chemical oxygen demand (COD) in wastewater is significantly elevated in paper mills due to the large amounts of organic matter, such as lignin, cellulose, and residual chemicals from pulping.

- Bleaching Effluent: Effluent from bleaching processes contains hazardous chemicals, particularly chlorine and chlorinated compounds like dioxins, which are highly toxic and persistent in the environment.

- Heavy Metals: Wastewater from the pulping process may contain trace amounts of heavy metals like copper, zinc, and chromium, which originate from the chemicals used in wood treatment or from corrosion in process equipment.

- Sludge Generation: The treatment of process water and wastewater produces large volumes of sludge, which is rich in organic and inorganic matter. Managing this sludge is a challenge because it often requires dewatering, disposal, or further treatment.

- Regulatory Compliance: The paper industry faces increasingly stringent regulations concerning effluent discharge limits for pollutants.

- Energy Efficiency: Many water treatment processes, such as aeration, pumping, and filtration, are energy-intensive. High energy consumption not only drives up operational costs but also increases the environmental footprint of the paper mill. Balancing treatment effectiveness with energy efficiency is crucial to maintaining cost-effectiveness and reducing carbon emissions.

Treatment Solutions

- Heavy Metal Removal: Chemical precipitation is one of the primary methods used to remove heavy metals from wastewater. This involves adding coagulants and flocculants to form insoluble metal compounds that settle out of the water.

- COD Reduction: Biological treatment methods, like activated sludge systems and biofilters, leverage the ability of microorganisms to break down organic pollutants. These systems, often used in aerobic conditions (where oxygen is present), degrade the organic matter in wastewater, reducing its COD levels before discharge or further treatment.

- Bleaching Effluent Treatment: For bleaching effluents, advanced oxidation processes (AOP) are used to degrade harmful chemicals like chlorine compounds. AOPs, such as ozonation or the use of hydrogen peroxide, generate powerful oxidizing agents that break down complex organic molecules, including persistent toxic compounds like dioxins.

- Ion exchange is another method used, particularly for low-concentration metals, where specific resins attract and remove heavy metal ions, ensuring the treated water is free from hazardous levels of metals.

- Sludge Management: To handle the large volumes of sludge produced, mills use technologies like sludge thickening and dewatering through centrifuges or belt filter presses. These processes reduce the water content of sludge, making it easier and more cost-effective to transport and dispose of.

- Monitoring and Control: Implementing real-time monitoring systems allows paper mills to continuously track key water quality parameters, such as pH, COD, and turbidity. These systems provide valuable data that helps optimize treatment processes, ensure regulatory compliance, and minimize the risk of process failures. Additionally, data management systems enable mills to analyze trends, identify inefficiencies, and implement timely corrective actions.

- Process Water Recycling: To minimize the use of fresh water, paper mills implement closed-loop systems that recycle process water. These systems typically employ microfiltration or ultrafiltration to remove suspended solids and contaminants, enabling the reuse of water within the production cycle.

Optimize your industrial process with our expert water treatment solutions, designed to improve efficiency and protect the environment. Contact us today to schedule a meeting and discover how we can help you achieve your goals!

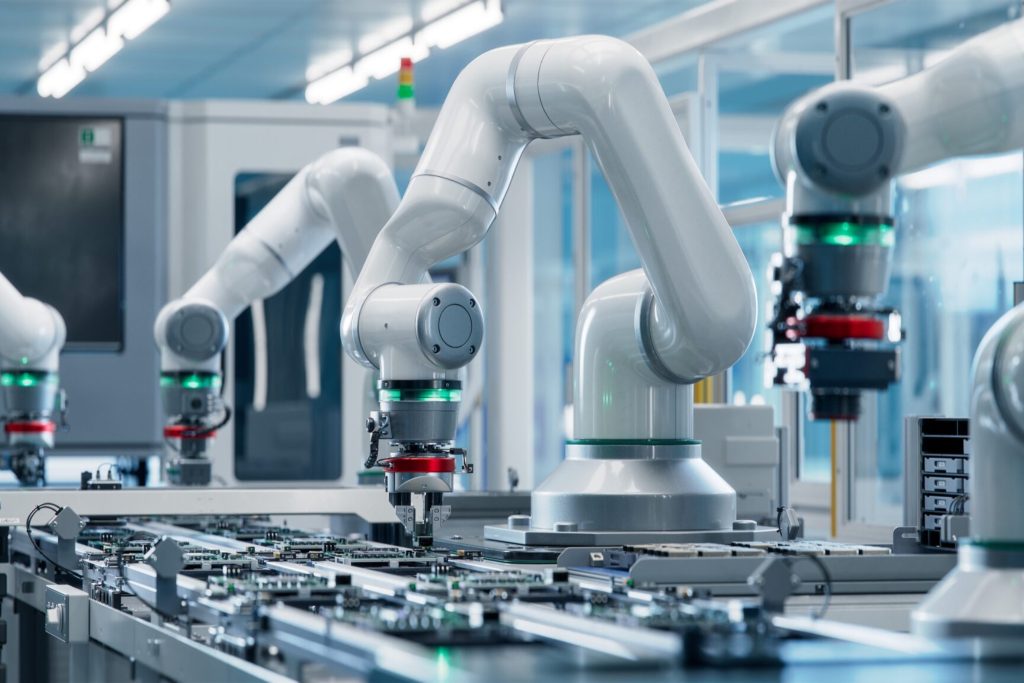

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for…

Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants…

Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the…

Paper

Water treatment plays a vital role in the paper industry, where large volumes of water…

Automotive

In the automotive industry, paint application is a crucial process that significantly influences the final…

Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety…

Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring…

Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with…

Metalcasting

Effective water treatment is essential in the metal casting industry to ensure optimal cooling and…