Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring operational efficiency, equipment longevity, and environmental compliance. Both industries rely heavily on water for processes such as cooling, steam generation, and wastewater management, making effective treatment crucial to mitigating contamination and preventing system failures.

Cooling water systems in petrochemical plants are particularly vulnerable to contamination due to exposure to various pollutants during production. In fertilizer plants, contaminants such as ammonia, nitrates, and phosphates can accumulate, leading to scaling, fouling, and corrosion. Similarly, oil refineries face challenges from dissolved solids and hydrocarbons that can degrade cooling systems. Proper management and treatment, including filtration, chemical dosing, and blowdown control, are necessary to maintain optimal heat exchange efficiency and prevent microbial growth.

Boiler water treatment is another critical aspect, as both fertilizer plants and refineries rely on high-pressure systems for steam generation. High-purity boiler feedwater is essential to prevent scaling, corrosion, and deposition in steam-generating equipment, which can lead to costly repairs and reduced efficiency.

Wastewater management presents a significant challenge in petrochemical facilities due to the presence of various pollutants. Fertilizer plants must address high concentrations of nitrogen compounds and heavy metals, while refineries contend with oils, sulfides, and organic contaminants. Advanced treatment techniques, including precipitation, ion exchange, biological treatment, and membrane filtration, are required to remove these pollutants and ensure compliance with environmental regulations.

Discover how KontrolKem’s innovative cooling water treatment solutions can enhance the efficiency and longevity of your industrial cooling systems.

>> Find out more

Learn how KontrolKem’s comprehensive boiler water treatment solutions, including advanced chemicals and equipment, prevent scale formation, corrosion, and other issues.

>> Find out more

High pressure boilers and steam purity challenges

Downtime is not an option: Steam generation is a cornerstone of refinery operations, supporting everything from distillation processes to critical chemical reactions. To maintain uninterrupted production, oil refineries rely heavily on high-pressure boilers often exceeding pressures of 100 bar. Any impurities in the water can lead to serious problems and that is why they require superb water pretreatment.

- Water clarification and filtration

- Water Softening

- Membrane treatment and antiscalants and biofilm control

- Continuous Electrodeionization and Mixed Bed Polishing

- Condensate polishing

- Continuous Monitoring: Advanced monitoring systems are essential for detecting and correcting issues in real-time. Parameters like pH, conductivity, and dissolved oxygen must be closely monitored to ensure compliance with operational standards.

- Oxygen scavangers for high pressure systems (eg. DEHA)

- Antifoamers for increase in cylces of concentrations and resource and energy sacings

- Neutralizing amines for condensate lines corrosion inhibition

Discover KontrolKem’s comprehensive wastewater treatment solutions, including advanced chemical treatments and equipment

>> Find out more

Petrochemical wastewater challenges

- High Salinity: Refineries remove significant amounts of salts during crude oil desalting and other processes, leading to wastewater with elevated salinity levels. High salinity can impair biological treatment systems and corrode equipment.

- Presence of Heavy Metals: Effluent often contains metals such as iron, nickel, and vanadium, originating from crude oil and catalyst residues. These metals are toxic to aquatic life and must be removed to meet discharge standards.

- Emulsified Oil: Emulsified oil forms stable mixtures with water, making separation challenging. These emulsions can clog equipment and interfere with biological treatment processes.

- Ammonia and Hydrogen Sulfide: Wastewater from hydroprocessing and cracking units contains high concentrations of ammonia and hydrogen sulfide, which are toxic and corrosive.

- Acidic Wastewater: Wastewater streams often have low pH, exacerbating corrosion risks and complicating treatment processes.

- Alkaline Wastewater: Streams from caustic washes contain organics, sulfides, and phenols, which contribute to high chemical oxygen demand (COD) and biological oxygen demand (BOD).

- Sludge and Solids Management: The presence of high oil content and sludge requires effective separation, dewatering, and handling to minimize environmental impact and disposal costs.

Treatment Solutions:

- Chemical Precipitation: Addition of precipitating agents to convert dissolved metals into insoluble forms, which can then be filtered out.

- Chemical Oxidation: Sodium hypochlorite or hydrogen peroxide oxidizes sulfides into non-toxic sulfates.

- Chemical Demulsifiers: Break the bonds between oil and water, allowing separation.

- API Separators: Use gravity-based methods to remove free oil and larger particles.

- Dissolved Air Flotation (DAF): Removes finer oil droplets and suspended solids using microbubbles to float contaminants to the surface.

- Activated Sludge Process: Aerobic bacteria metabolize organic pollutants, reducing COD and BOD.

- Dewatering Systems: Include belt presses or decanters to handle high solids content and minimize waste.

- Advanced Filtration: Sand or multimedia filters remove remaining fine particulates, ensuring water clarity.

- Membrane Bioreactors (MBRs): Combine filtration and biological treatment for removing fine organic particles and nutrients.

- Advanced Oxidation Processes (AOPs): Use ozone, UV, or hydroxyl radicals to break down trace organics and refractory pollutants.

Optimize your industrial process with our expert water treatment solutions, designed to improve efficiency and protect the environment. Contact us today to schedule a meeting and discover how we can help you achieve your goals!

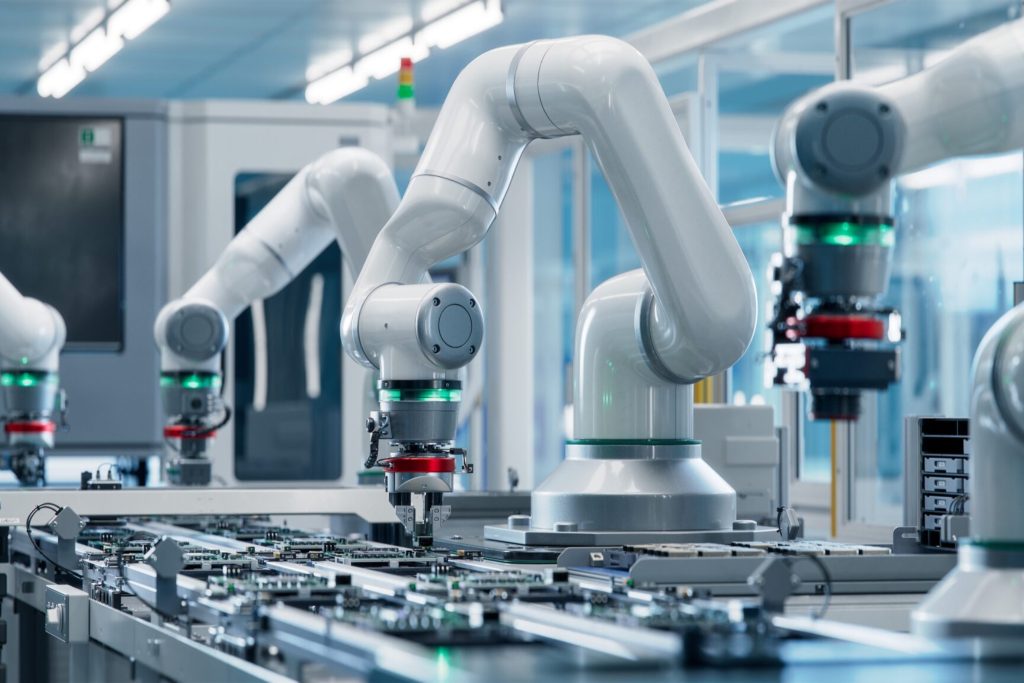

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for…

Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants…

Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the…

Paper

Water treatment plays a vital role in the paper industry, where large volumes of water…

Automotive

In the automotive industry, paint application is a crucial process that significantly influences the final…

Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety…

Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring…

Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with…

Metalcasting

Effective water treatment is essential in the metal casting industry to ensure optimal cooling and…