Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety of products at every manufacturing stage. Water serves multiple purposes, including acting as a raw material, a cleaning agent, and a solvent, making its quality crucial to the effectiveness of pharmaceuticals. Various water types, such as Purified Water (PW) and Water for Injection (WFI), must comply with stringent regulatory standards established by organizations like the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP). Proper treatment processes are essential for preventing contamination, microbial growth, and endotoxin presence, which can adversely affect drug formulations. Additionally, effective water management in systems like boilers and cooling units is essential for maintaining operational efficiency and regulatory compliance.

To achieve these quality standards, pharmaceutical companies implement rigorous treatment protocols for different types of water. PW and WFI are subjected to advanced purification methods to ensure they meet necessary purity levels. Maintaining sterility involves regular sanitization and biofilm prevention strategies, while the control of endotoxins and total organic carbon (TOC) levels is critical for compliance with safety regulations. Continuous monitoring of water systems, coupled with appropriate design and materials, further ensure the integrity of pharmaceutical-grade water. Ultimately, adherence to Good Manufacturing Practice (GMP) standards and meticulous documentation is fundamental to guaranteeing the safety and efficacy of pharmaceutical products.

Discover how KontrolKem’s innovative cooling water treatment solutions can enhance the efficiency and longevity of your industrial cooling systems.

>> Find out more

Learn how KontrolKem’s comprehensive boiler water treatment solutions, including advanced chemicals and equipment, prevent scale formation, corrosion, and other issues.

>> Find out more

Water treatment for pharmaceutical production

Challenges:

- Purified Water (PW): Used in the preparation of non-sterile drug products, requiring high microbial purity and low levels of organic and inorganic impurities.

- Water for Injection (WFI): This is the highest quality water, used in the production of parenteral (injectable) products. WFI must be free from microbial contamination, pyrogens (endotoxins), and particulates. The most critical regulation for is pyrogen removal.

- Standards: Compliance with regulations such as those from USP and EP is mandatory. Each defines specific conductivity, TOC, and microbial limits for different water types.

- Sanitization: Regular sanitization of the water system using heat (hot water or steam) or chemical methods.

- Biofilm Prevention: Biofilms in piping systems can harbor bacteria and endotoxins, requiring continuous efforts to prevent and eliminate biofilm formation. Smooth piping materials, proper flow rates, and regular sanitization help manage this risk.

- Endotoxin Removal Critical for Parenteral Products: Endotoxins (pyrogens) from Gram-negative bacterial cell walls must be rigorously controlled, particularly in WFI.

- Organic Contaminant Removal: The pharmaceutical industry requires strict control of TOC levels to ensure water purity. This is achieved through continuous or periodic monitoring of TOC levels ensures that organic contaminants do not exceed regulatory thresholds.

Treatment Solutions:

- Material Selection: Pipes and storage tanks are typically made of 316L stainless steel or other materials with a smooth, inert surface to prevent contamination and biofilm formation.

- Sanitary Design: The system should be designed for easy drainage and sanitization, with minimized dead legs (sections where water can stagnate).

- Control of Flow Rate and Pressure: Proper flow rates are necessary to prevent stagnation, which could lead to microbial growth or particle deposition.

- Pre-treatment: Removal of large particulates, chlorine, and other chemicals through filtration, softening, or activated carbon to protect downstream processes. Methods such as ultrafiltration, distillation, or reverse osmosis are used for pyrogen removal.

- Electrodeionization (EDI): Often used after RO to polish water by further reducing ion content.

- Distillation: Commonly used for producing WFI, as it is highly effective in removing all forms of contaminants, including pyrogens.

- Point-of-Use Filtration: Sterile filters (typically 0.22 µm) are often used at points of use to remove bacteria just before water enters a manufacturing process.

- UV sterilization: or final filtration to maintain sterility at the point of use.

- Routine Sampling: Water systems are sampled at regular intervals to test for microbial load, conductivity, TOC, and endotoxins.

- Critical Control Points (CCPs): Identifying and monitoring CCPs in the water system where contamination is most likely to occur is a key part of validation.

- Regular Audits: Systems are audited for compliance with regulatory standards, including the design, operation, and maintenance of the water treatment system.

- GMP (Good Manufacturing Practice): Water treatment systems must comply with GMP standards. This includes thorough documentation of system design, validation, operation, and maintenance.

- TOC Monitoring: Continuous or periodic monitoring of TOC levels ensures that organic contaminants do not exceed regulatory thresholds.

Optimize your industrial process with our expert water treatment solutions, designed to improve efficiency and protect the environment. Contact us today to schedule a meeting and discover how we can help you achieve your goals!

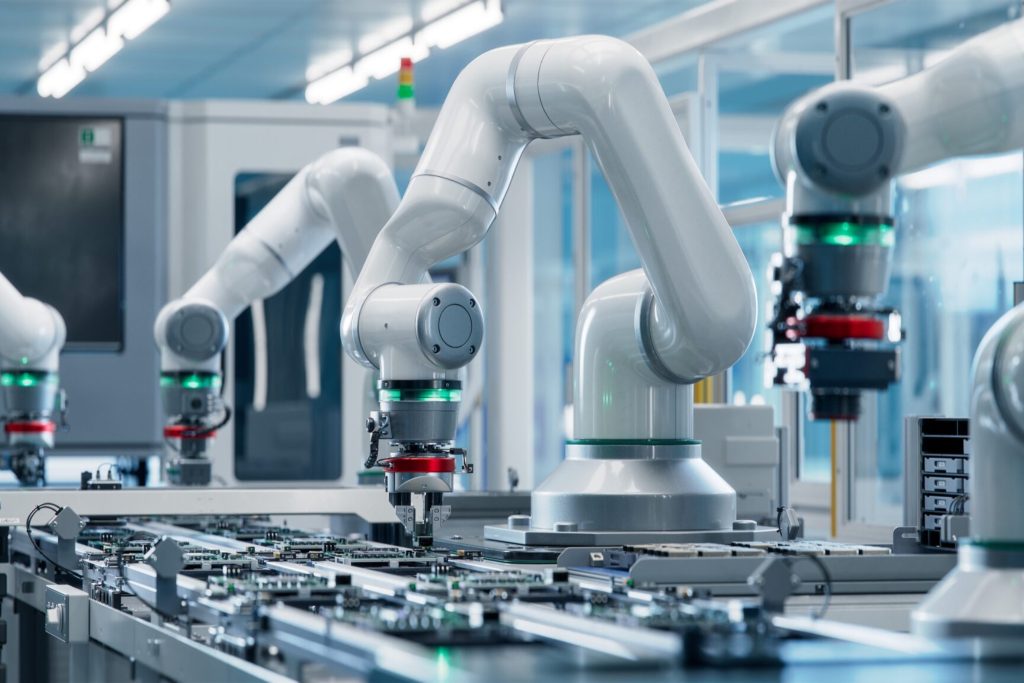

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for…

Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants…

Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the…

Paper

Water treatment plays a vital role in the paper industry, where large volumes of water…

Automotive

In the automotive industry, paint application is a crucial process that significantly influences the final…

Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety…

Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring…

Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with…

Metalcasting

Effective water treatment is essential in the metal casting industry to ensure optimal cooling and…