Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with environmental regulations. High-quality water is crucial for steam generation, cooling systems, and various auxiliary processes. Treatment removes impurities that can cause corrosion, scaling, and fouling, which may impair equipment performance and increase maintenance costs.

Given the high pressures and temperatures in these systems, even minor contaminants can lead to significant operational challenges. Power plants also face stringent regulations regarding water usage and discharge, requiring advanced treatment techniques to meet environmental standards. Technologies like reverse osmosis, ion exchange, and advanced filtration are commonly employed to achieve the necessary water quality. Ongoing monitoring systems ensure consistent water quality throughout plant operations. Effective water treatment is vital not only for operational efficiency but also for promoting ecological sustainability.

Discover how KontrolKem’s innovative cooling water treatment solutions can enhance the efficiency and longevity of your industrial cooling systems.

>> Find out more

Learn how KontrolKem’s comprehensive boiler water treatment solutions, including advanced chemicals and equipment, prevent scale formation, corrosion, and other issues.

>> Find out more

High pressure boiler water and steam turbines challenges

- Scaling and Deposition: Dissolved minerals such as calcium, magnesium, and silica cause scale deposits on boiler tubes, reducing heat transfer efficiency and increasing energy consumption.

- Corrosion: Dissolved gases like oxygen and carbon dioxide in feedwater lead to corrosion of boiler and steam systems, resulting in damage and reduced equipment lifespan.

- Carryover and Foaming: Impurities, along with foam caused by high dissolved solids, lead to carryover in steam, causing deposits in turbines and other equipment.

- Silica and Sodium Contamination: High levels of silica and sodium in feedwater contribute to deposition on turbine blades and other steam system components.

- Iron and Copper Oxides: Corrosion of feedwater and condensate return systems introduces iron and copper oxides, which can deposit in boilers and steam lines.

Treatment Solutions

- Oxygen Scavengers: Removes dissolved oxygen using chemicals such as hydrazine, sulfite, or their alternatives.

- Corrosion Inhibition: Protect metal surfaces from oxidation and corrosion and ensures pH control and minimizes corrosion with use of amines, phosphates, or specialized filming inhibitors.

- Anti-Foam Agents: Add antifoaming chemicals to the boiler water treatment program Prevent foaming that leads to steam impurities and carryover and increase cycles of concentrations and reducing blowdown and energy loss.

- Reverse Osmosis: Achieve ultra-pure water by removing dissolved solids by using reverse osmosis membranes for feedwater pre-treatment.

- CEDI (Continuous Electrodeionization) and Mixed Bed Polishing: Use CEDI and mixed-bed resin systems for final polishing to achieve extremely low levels of ionic contamination to produce ultrapure water for high-pressure boilers.

- Condensate Polishing: By employing an ion exchange resin or filtration systems to maintain high condensate purity by removing dissolved impurities such as silica and metals (iron, copper).

- Conductivity/ Silica/ Sodium Monitoring: Use online conductivity meters to detect contamination and trigger corrective actions by continuously monitoring condensate and feedwater purity to prevent turbine blade deposits.

- Blowdown Systems: Automated blowdown controls optimize water removal while maintaining boiler efficiency to minimize dissolved solids and prevent scale and carryover.

Optimize your industrial process with our expert water treatment solutions, designed to improve efficiency and protect the environment. Contact us today to schedule a meeting and discover how we can help you achieve your goals!

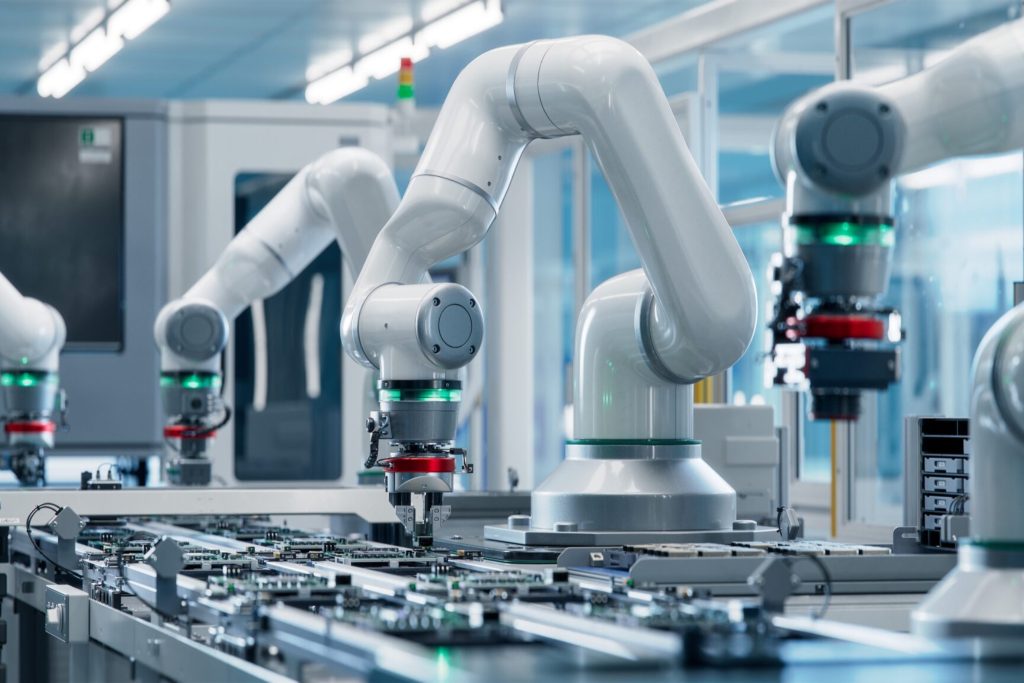

Electronics Industry

Water treatment in the electronics industry is critical due to the strict purity requirements for…

Electroplating Industry

Water treatment in the electroplating industry is a highly specialized process, addressing the unique contaminants…

Geothermal

The geothermal industry plays a crucial role in the transition to renewable energy, utilizing the…

Paper

Water treatment plays a vital role in the paper industry, where large volumes of water…

Automotive

In the automotive industry, paint application is a crucial process that significantly influences the final…

Pharmaceutical Industries

Water treatment is a vital aspect of the pharmaceutical industry, ensuring the purity and safety…

Petrochemical

Water treatment in petrochemical facilities, including fertilizer plants and oil refineries, is essential for ensuring…

Power Plants

Water treatment in power plants is essential for ensuring operational efficiency, safety, and compliance with…

Metalcasting

Effective water treatment is essential in the metal casting industry to ensure optimal cooling and…